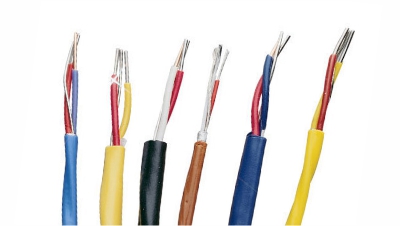

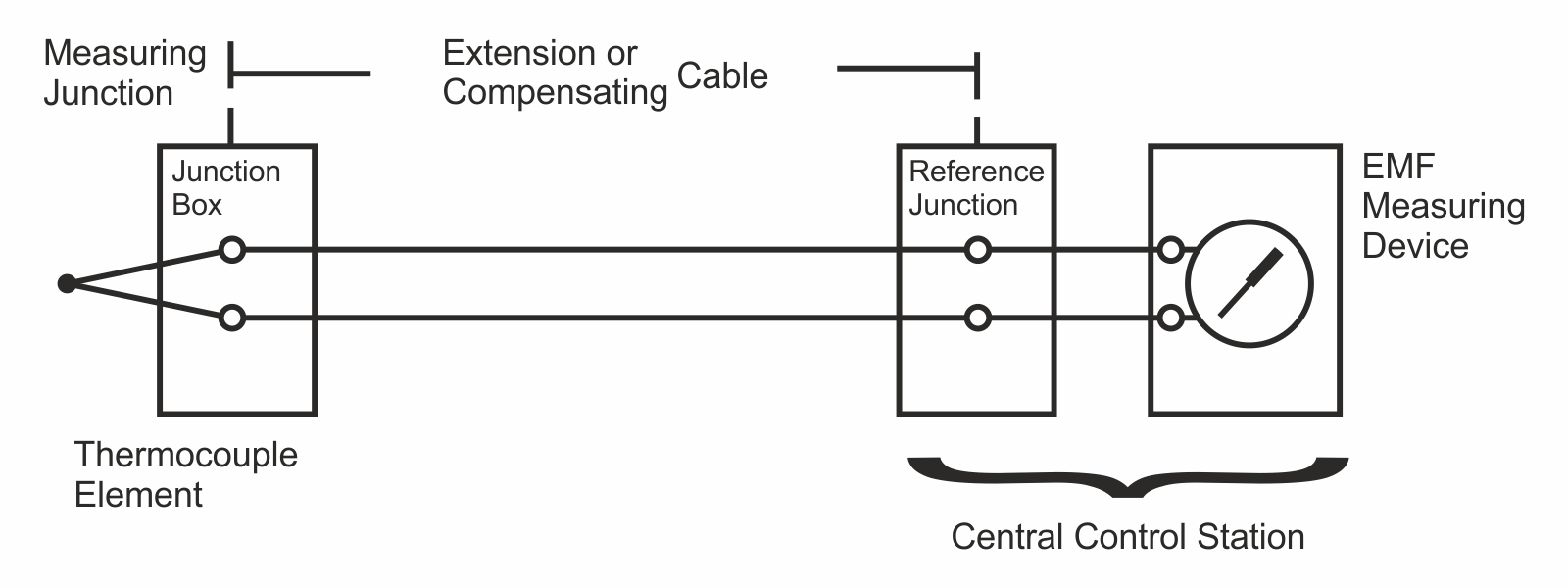

Now to avoid any error, theoretically the wires of the same metals forming the Thermocouple should be extended up to the measuring instruments. In this case the connecting wires are called Thermocouple Extension Leads. This is applicable to type J, T and E thermocouple.

But in case of costly metals used for K, R, S and B thermocouple, less expensive metals having the same EMF characteristics as that of Thermocouple metals between 0 to 100 C are used for connecting the thermocouple to the instruments. These connecting wires are called compensating cables.

Conductor Size for extension wires & compensating cables :

To day direct measurement of emf is the most popular method and in this case the size of the connecting wires has no bearing on the accuracy of the measurement and hence the size of the conductor is to be chosen keeping in mind the mechanical stability.

The most common conductor size for a single pair cable is 16 awg (1/1.29 mm) and for multipair cable it is 20 awg (1/0.81 mm)

Solid wire construction is recommended for extension wire and compensating cable, as in case of multi strand conductor if there is a slight variation in the composition of the strands, they form their own internal thermocouples and may add to the error.

The adjoining table gives the colour code for extension wires and compensating cables as per different standards adopted by different countries.

In India mostly ANSI (American National Standard Institute) specification MC 96.1 is followed.

No Comments

Sorry, the comment form is closed at this time.